LIMWE – Kenya

€14.00 – €53.00

Dark Chocolate, Brown Sugar, Black Berry, Butter, Lemon

COFFEE GRADE: AB

FARM: 100% Limwe Estate

VARIETAL: Batian, Ruiru 11

PROCESSING: Fully washed

ALTITUDE: 2,070 meters

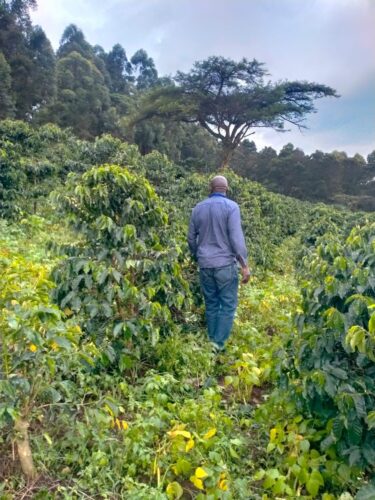

OWNER: Livien Osiemo

REGION: KisiiNyamira

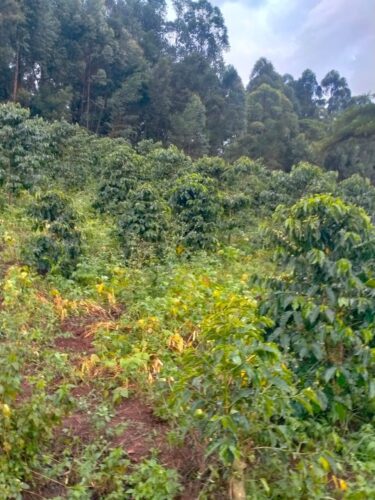

FARM SIZE: 8 hectares

Additional information

Livien Osiemo has long dreamed of having a coffee farm. At Limwe Estate, he is fulfilling his dream while striving towards excellence. In 2015, he purchased Limwe Estate and planted the first coffee trees on the farm. The farm is spread across five plots in Nyamira County. Together, they make up about 8 hectares of coffee plantings.At the high altitudes of 2,070 meters above sea level, pests and coffee diseases are minimal. Therefore, use of pesticides and fungicides are low and largely unneeded. With help from our partner, Kahawa Bora Millers, Livien also has access to training about improved pruning, cultivation and harvesting methods. Kahawa Bora’s field staff have also performed soil analysis on small estates to inform correct input application, which helps improve yields and quality while reducing cost and environmental impact. This focus on high quality at all stages of cultivation and processing has increased cup scores in a short period of time.

Cherrys is selectively handpicked and then pulped. Coffee is fermented for 12 to 24 hours in a small tank before being washed in clean water to remove any remaining mucilage. All wastewater from the washing process is cleaned to ensure environmental impact is limited.Parchment is soaked in clean water for 12 to 14 hours and then transferred to raised beds where it sundries for 21 to 30 days. As it dries, parchment is turned regularly to ensure even drying.