NEMBA – Burundi

€15.00 – €54.00

Grape, Hibiscus, Black Tea, Black Berries

SCA Score: 87

COFFEE GRADE: FW Scr. 15+

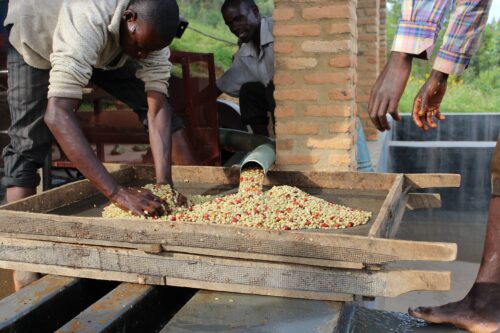

STATION: 100 % Nemba washing station

VARIETAL: Red Bourbon

PROCESSING: Fully washed

ALTITUDE: 1,700 meters

REGION: Kayanza

Additional information

Nemba station lies in the northern province of Kayanza. The lead agronomist oversees the implementation of Good Agricultural Practices (GAPs) and farmer education. They collaborate with the producers to ensure they have access to the necessary farming tools. The agronomist also helps farmers determine and implement the practices best suited to the specific growing conditions of their farming plots. Nemba uses a monitoring system to ensure traceability all along the production and processing chain. All 3,000+ producers are smallholders who own an average of 150 coffee trees. The farmers delivering cherry to Nemba are all located around 1,700+ meters above sea level, near the Kibila forest. The washing station has over 200 drying tables and can process up to 750 metric tons of cherry annually.